Design for Manufacturability – Reduce Costs Through Smart Engineering

A simple geometry saves time, tool wear, and cost.

With the design guidelines from 2DCNCPARTS.COM

you can optimize your CNC-milled parts for efficient and precise production.

A simple geometry saves time, tool wear, and cost.

With the design guidelines from 2DCNCPARTS.COM

you can optimize your CNC-milled parts for efficient and precise production.

The simpler the part, the shorter the machining time and the lower the cost.

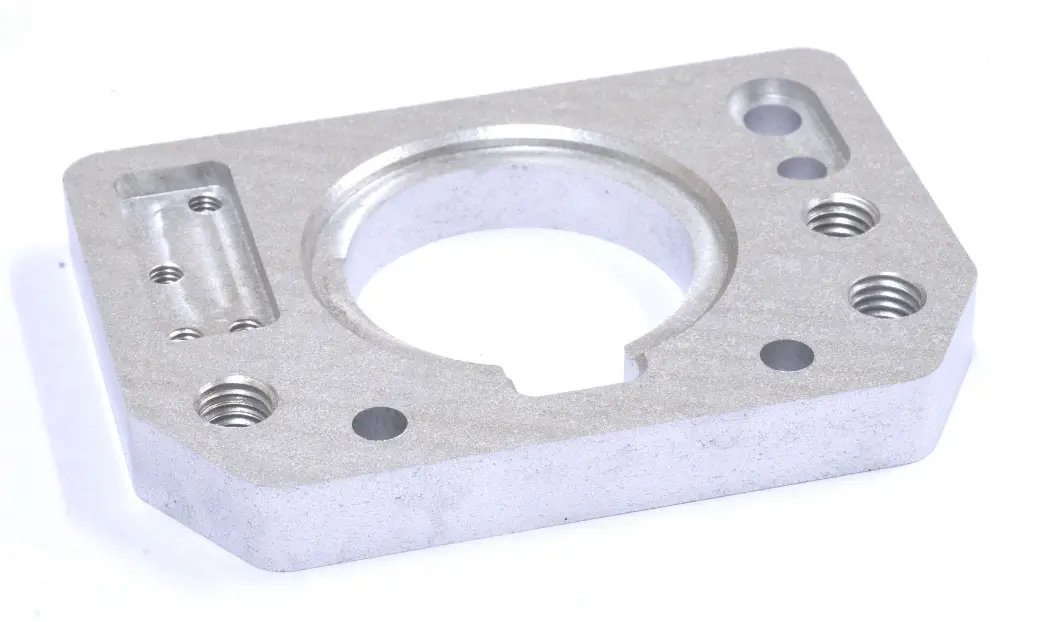

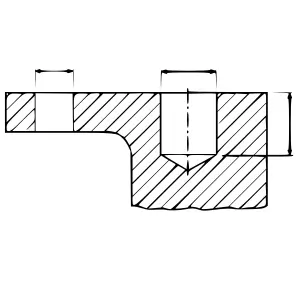

2DCNCPARTS.COM produces 2D CNC parts in multiple machining levels.

To achieve the most cost-effective manufacturing process, consider the following tips:

This option is the most efficient, as multiple parts can be milled in one setup.

We recommend large inner radii (≥ 4 mm) and standard material thicknesses

to reduce tool changes and machining time.

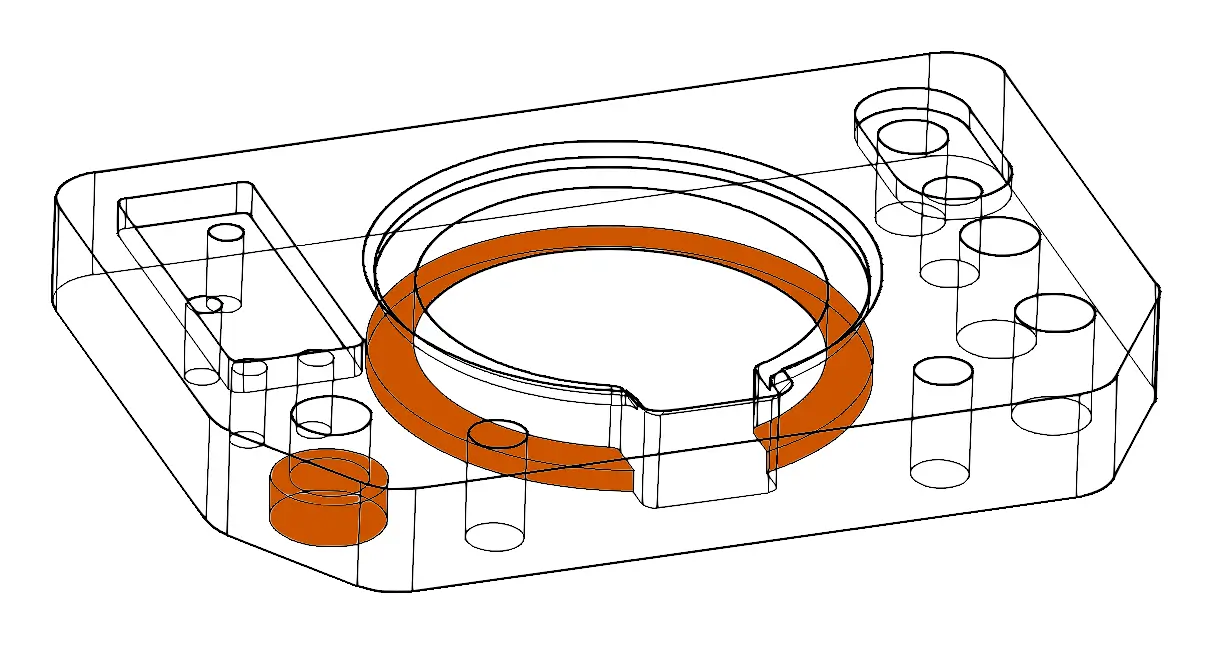

Double-sided machining requires precise alignment and increases setup time.

From the back side, only internal contours such as pockets, holes, or threads can be milled.

For such parts, we provide a custom quote upon request.

Side holes, fits, or threads are possible but require an additional setup.

We machine according to your CAD geometry, provided the areas are accessible in the setup.

Extra cost for single parts: €2 per hole, €4 per thread.

Using vacuum clamping, we manufacture parts from a minimum size of 20 x 20 mm.

Smaller parts can be reviewed and produced manually upon request.

Maximum size: 950 x 450 x 20 mm.

Our software automatically verifies these limits during upload.

2DCNCPARTS.COM manufactures CNC parts with high dimensional precision.

Minor deviations from the CAD model are process-related.

Typical tolerance: ±0.05 mm per 100 mm

Guaranteed: ±0.1 mm per 100 mm at room temperature

Fits: Reamers Ø2–30 mm (H7) in 1 mm increments.

Larger diameters milled to H9 precision.

Surcharge: €2 per fit.

Fits are randomly inspected during production.

Deviations above +0.02 mm are considered out of tolerance and may be claimed.

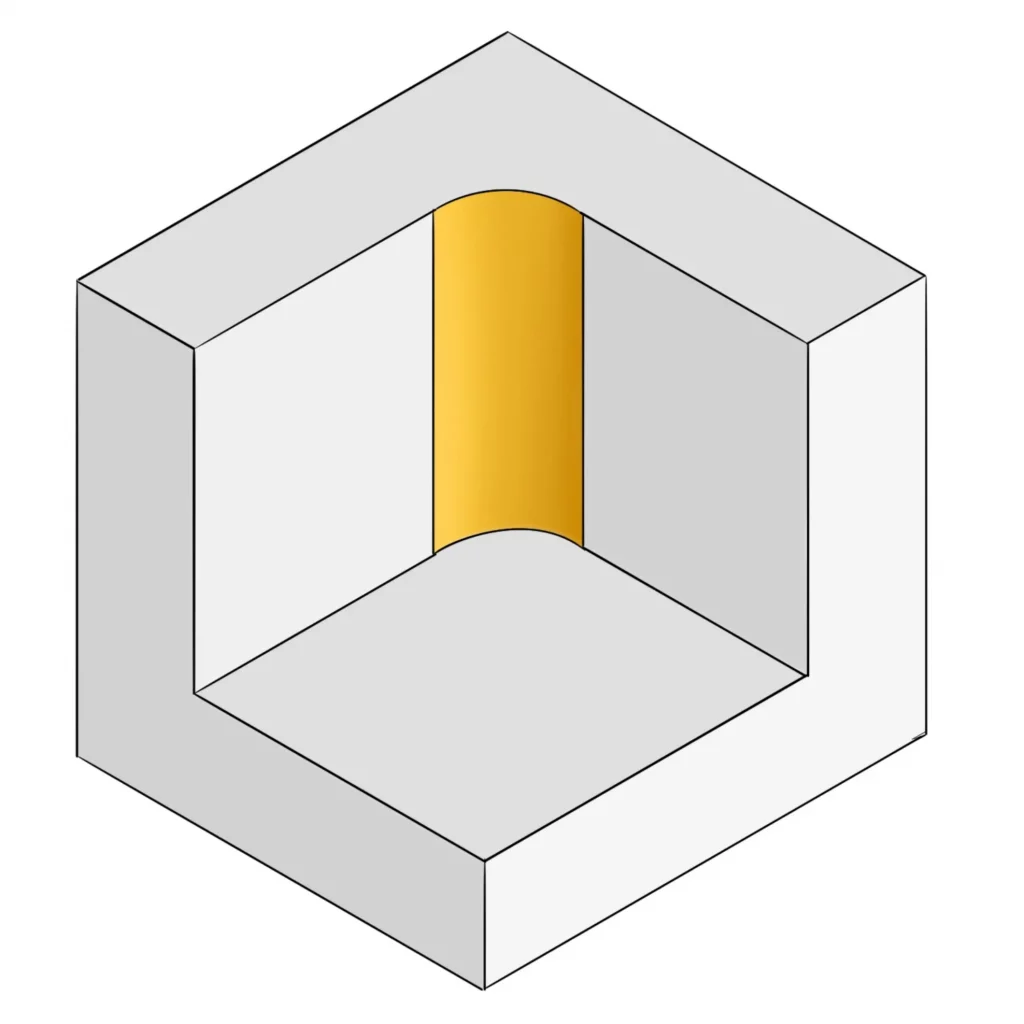

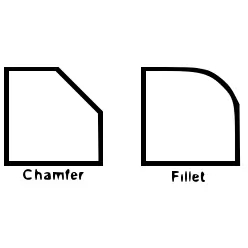

At 2DCNCPARTS.COM, corners and contours are automatically milled with a cutting tool.

This results in small roundings in inner corners — sharp inner edges are not technically possible.

For cost efficiency, we recommend designing with an inner radius of at least 4 mm.

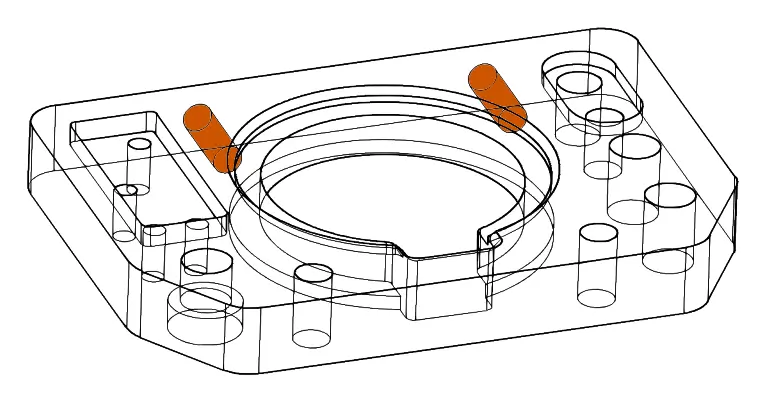

2DCNCPARTS.COM machines holes and fits precisely as defined in your CAD model.

Holes are drilled, milled, or reamed depending on size.

Reamers Ø2–30 mm (H7) in 1 mm steps.

Larger diameters: H9 precision.

Surcharge: €2 per fit.

Fits are randomly inspected during production.

Deviations above +0.02 mm are considered out of tolerance and may be claimed.

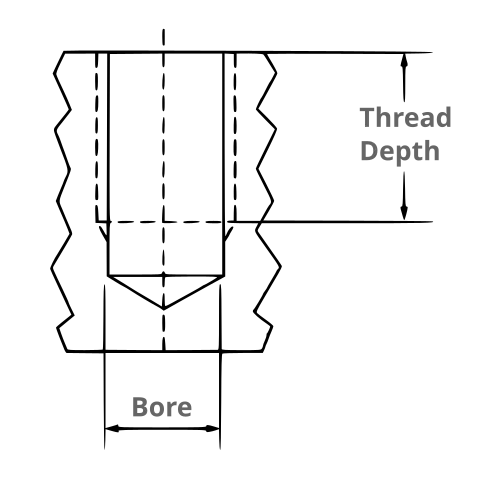

2DCNCPARTS.COM produces metric threads from M3 to M12 directly during milling.

We currently require a core hole in the model and a position sketch or drawing.

Note: Modeled threads (e.g. Fusion 360) are not automatically detected.

Please disable modeled threads before exporting the STEP file.

We recommend adding text only when technically necessary (e.g., labels or alignment marks).

Our software currently does not recognize text automatically.

Text with a minimum line width of 1.1 mm can be milled,

recommended engraving depth: 0.2 mm.

Smaller engravings may appear incomplete.

2DCNCPARTS.COM applies a standard edge break of 0.1 mm to all parts.

Optional chamfers up to 0.3 mm are available if functionally required.

Additional chamfers or radii increase machining time and are typically only needed

for fits, sealing surfaces, or manual handling.

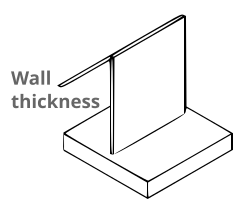

We recommend a minimum wall thickness of 1 mm to avoid instability during manufacturing.

All aluminum parts are mechanically deburred, chemically post-treated, and cleaned after milling.

This results in smooth, consistent edges.

Slight color variations or fine machining marks are process-related and normal.

Minor scratches or tool marks may remain and are technically unavoidable.